2D/3D Industrial X-ray Scanning Service

For those interested in non-destructive analysis of their parts, we offer a cost-effective solution. Gain deep insights into internal structures of your sample through our X-ray scanning solutions.

X-ray technologies are the best option for advanced, non-destructive imaging in industrial applications. Digital radiography and CT scanning provide precise, high-resolution insights into internal structures. Without damaging or altering your sample, we are able to examine intricate components and details that may not be visible through traditional methods.

We’re here to provide accurate, high-quality imaging solutions tailored to your needs.

Our Solution

Samples

up to 50 kgs

dimensions from milimiters to 50 x 80 cm

Innovative testing solutions

In situ and 4D experiments

automated X-ray serial testing

Resolution

possible resolution 0.3 µm with Field of View min. 0.7 mm x 0.9 mm

Wide variety of outcomes

detailed STL models

images/videos/analysis reports

Find out more about the CT principle

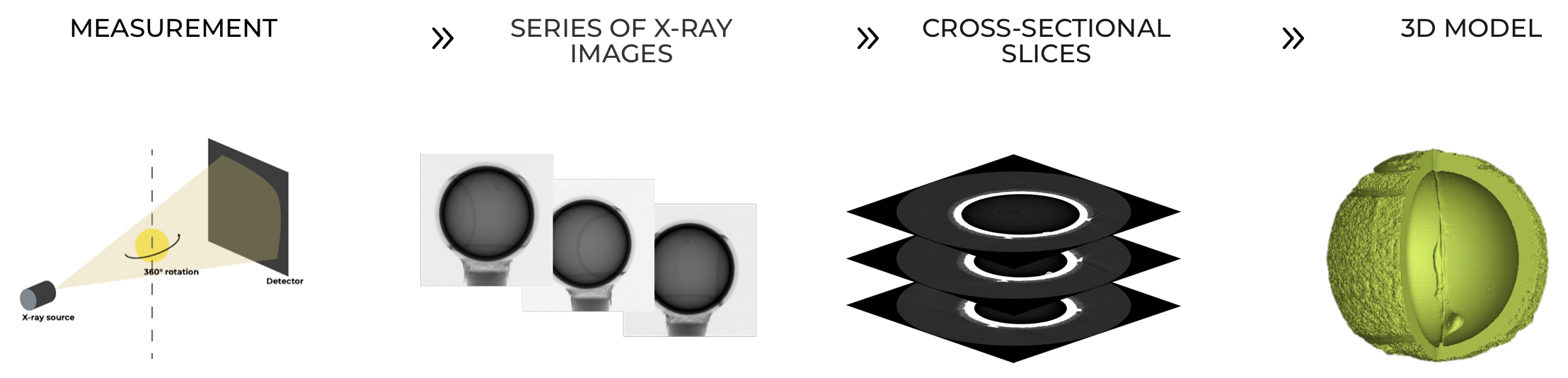

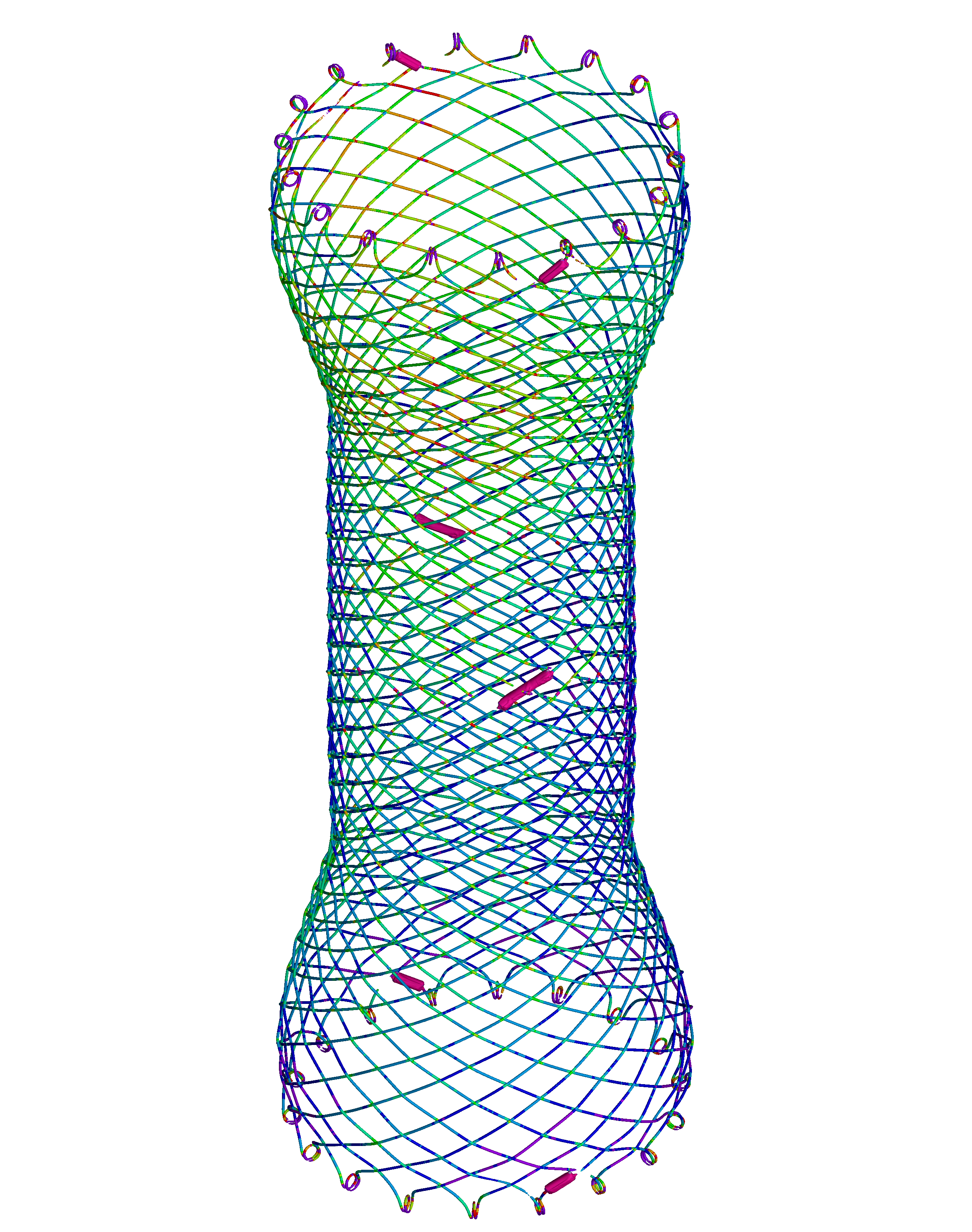

Industrial CT captures a series of X-ray images from different angles while the sample rotates around its axis. Subsequently using advanced reconstruction algorithms, it is possible to compute detailed cross-sectional slices. These slices together create a 3D digital volume.

Metrological validation

Internal and external inspection of parts for defect detection and measure dimensional deviations:

-

-

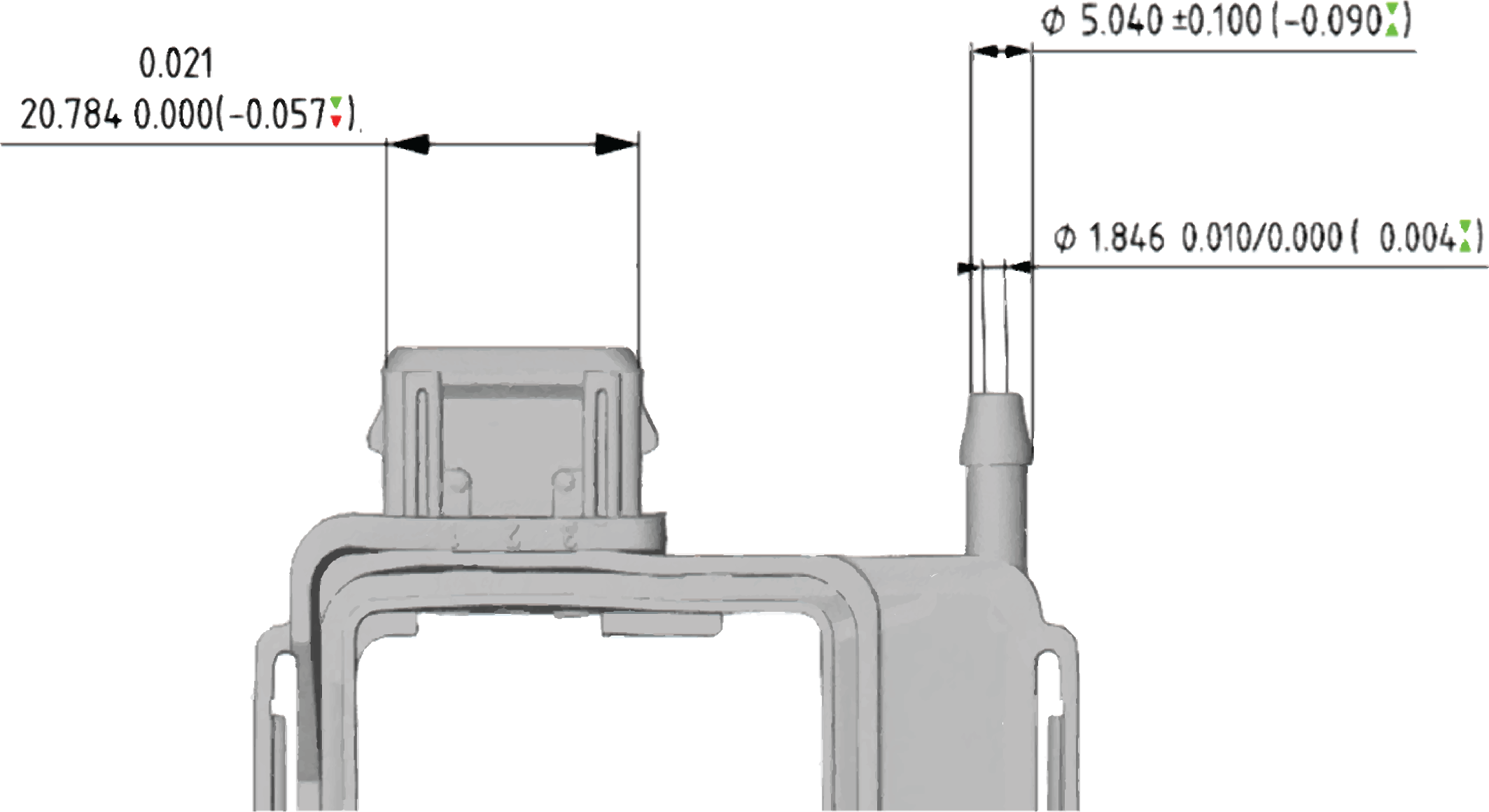

- High-precision measurements – Analysis of dimensions, porosity, and defects with micrometer accuracy. Analysis according to industrial standards.

- Quality control – Validation of parts against to 2D drawings or CAD models to to detect deviations and identify manufacturing issues.

-

Reverse engineering

Precise digital reconstruction of complex parts without disassembly:

-

-

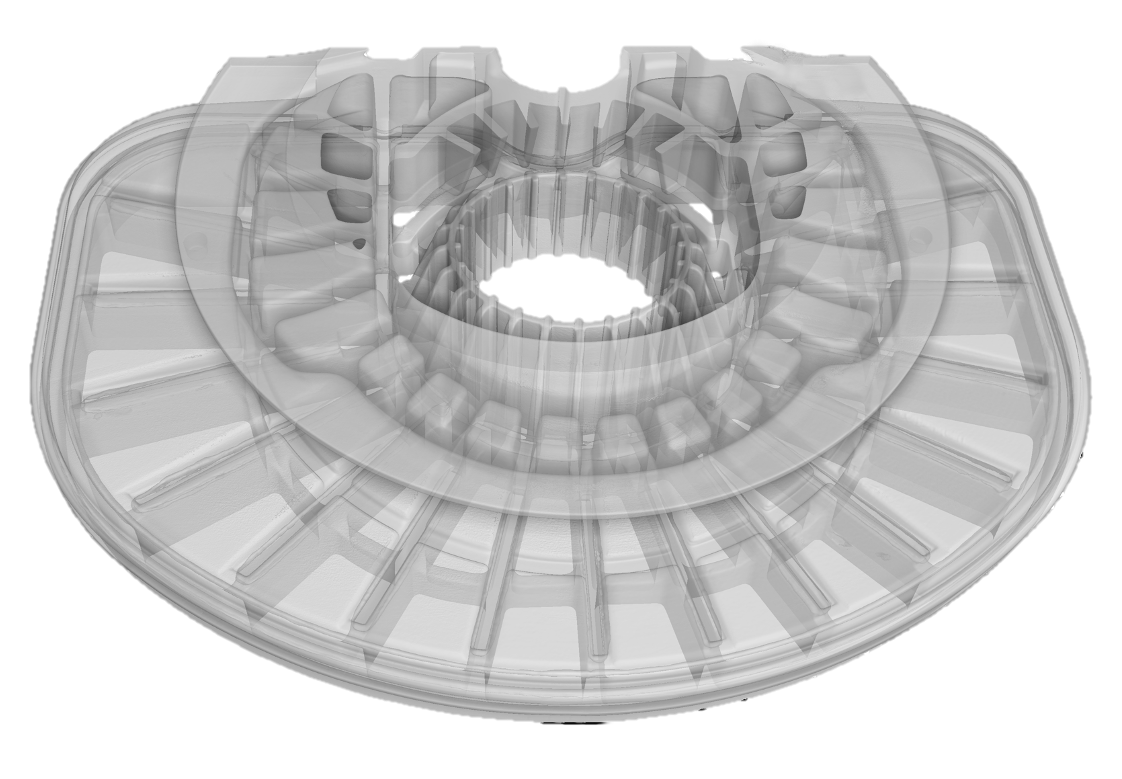

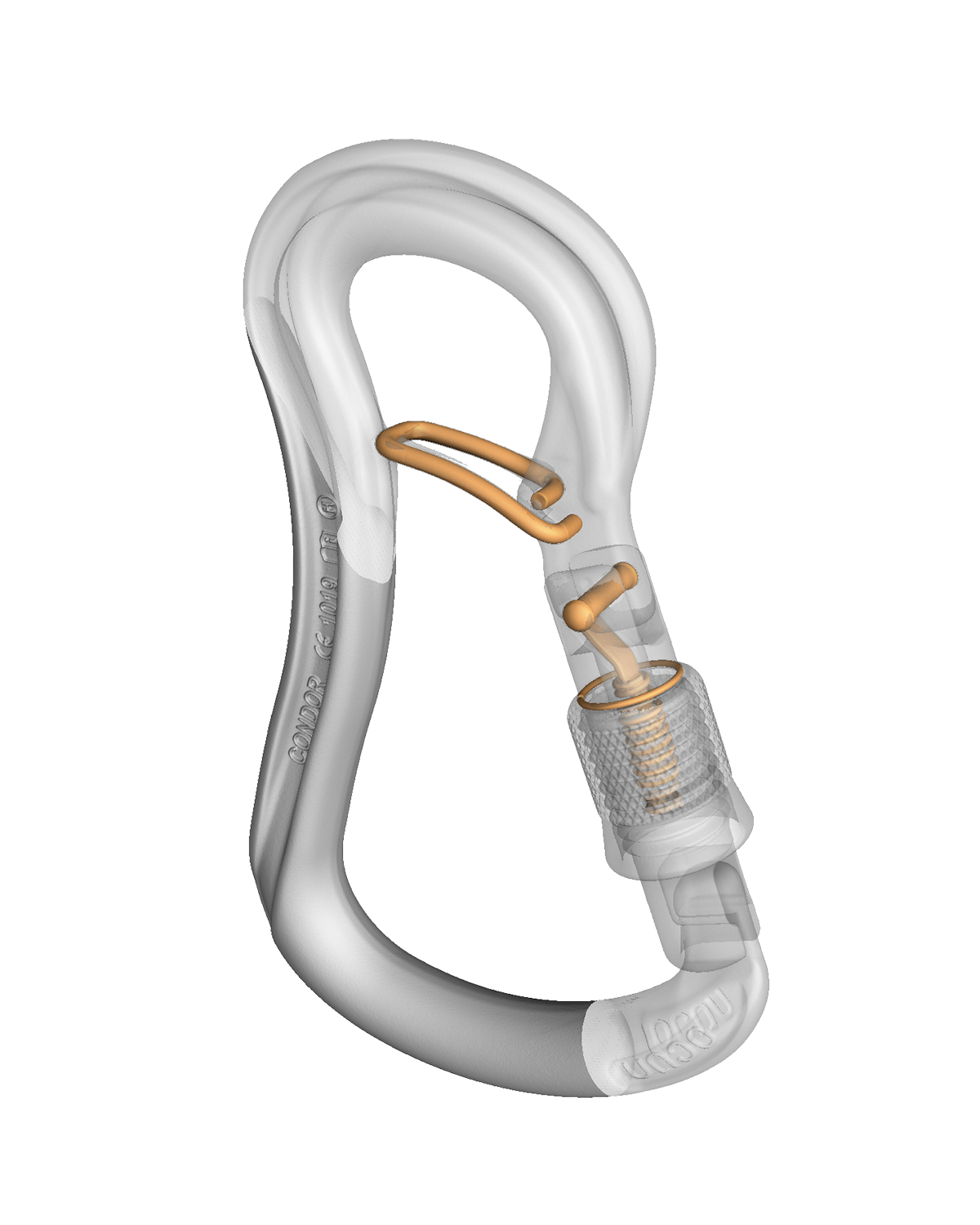

- Complete 3D digitization – Capturing external and internal geometries to create highly detailed digital 3D models without damaging the original part.

- Reconstruction of lost documentation – New technical drawings and CAD files generation for legacy or unavailable parts.

-

Components analysis

Complete view of a component’s internal structure, material distribution, and assembly quality:

-

-

- Assembly verification – Verification of solder joints, welds, bonds, and internal connections integrity without disassembly.

-

- Dynamic X-ray testing – Analysis of components under mechanical load, temperature variations, or operational conditions in real time.

-

Material inspection

Deep understanding of a material’s internal composition:

-

-

- Fiber orientation & density variations – Analysis of material distribution, detection of inconsistencies, and optimization of production quality.

- Dynamic & in-situ CT – Observation of material behaviour under stress, temperature changes, or mechanical load in real time.

-

Find out more about CT technology and its applications

4 Steps are all it takes:

Consult

Contact our experts via e-mail or phone to discuss your application and needs, and we’ll design the best solution for your requirements.

Send

Once the plan is designed, simply send us the part(s).

Scan

After delivery, we will measure your part(s) and perform analysis according to your needs.

Results

We’ll return the part(s) and provide a complete analysis, images, and tables.

Contact us

See our other products

Choose your industrial nano and micro-CT accessories from our diverse offer!