3D X-ray Computed Tomography Service

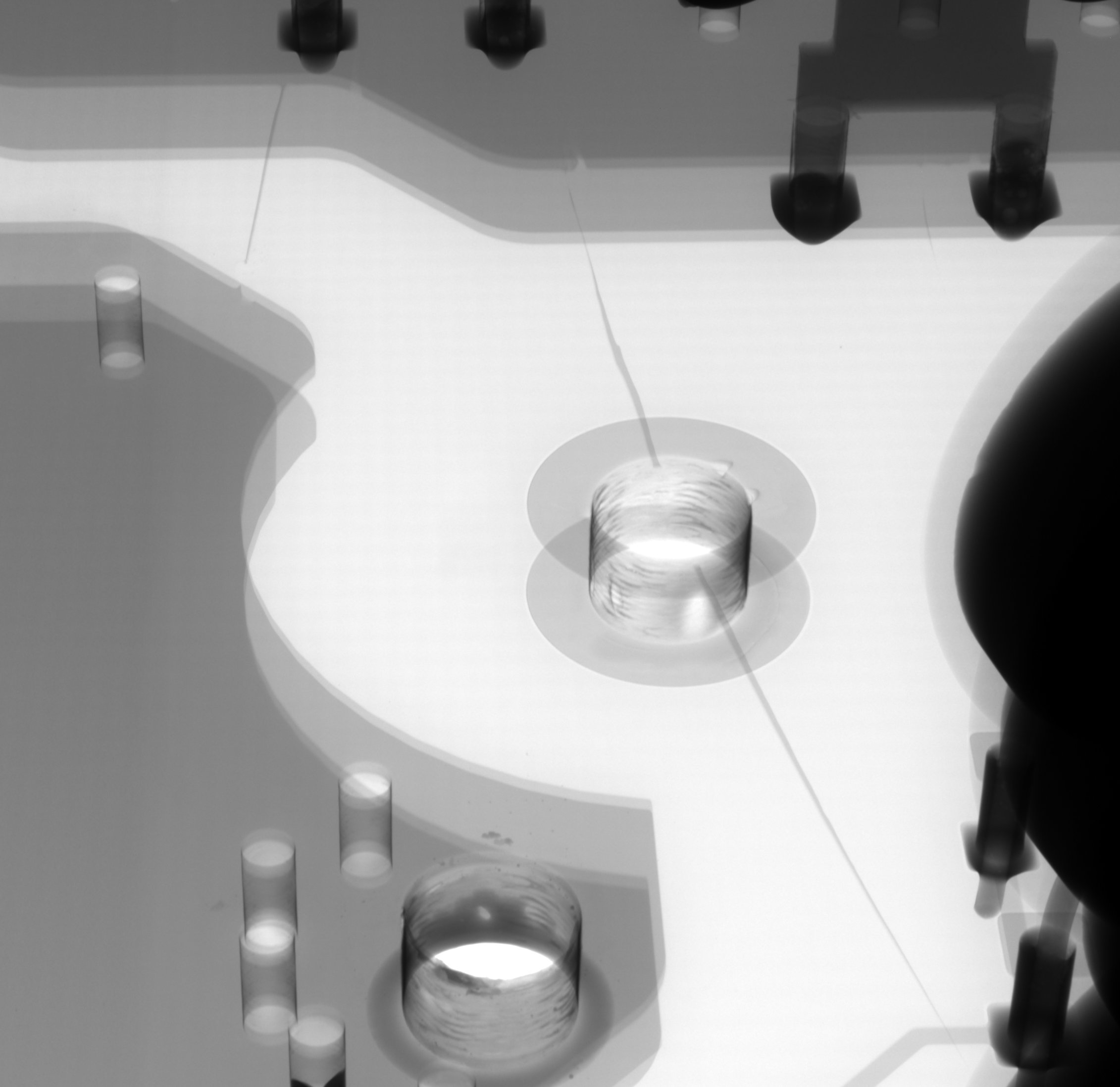

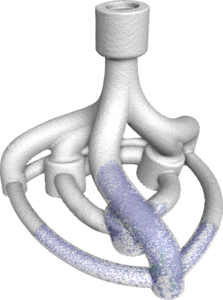

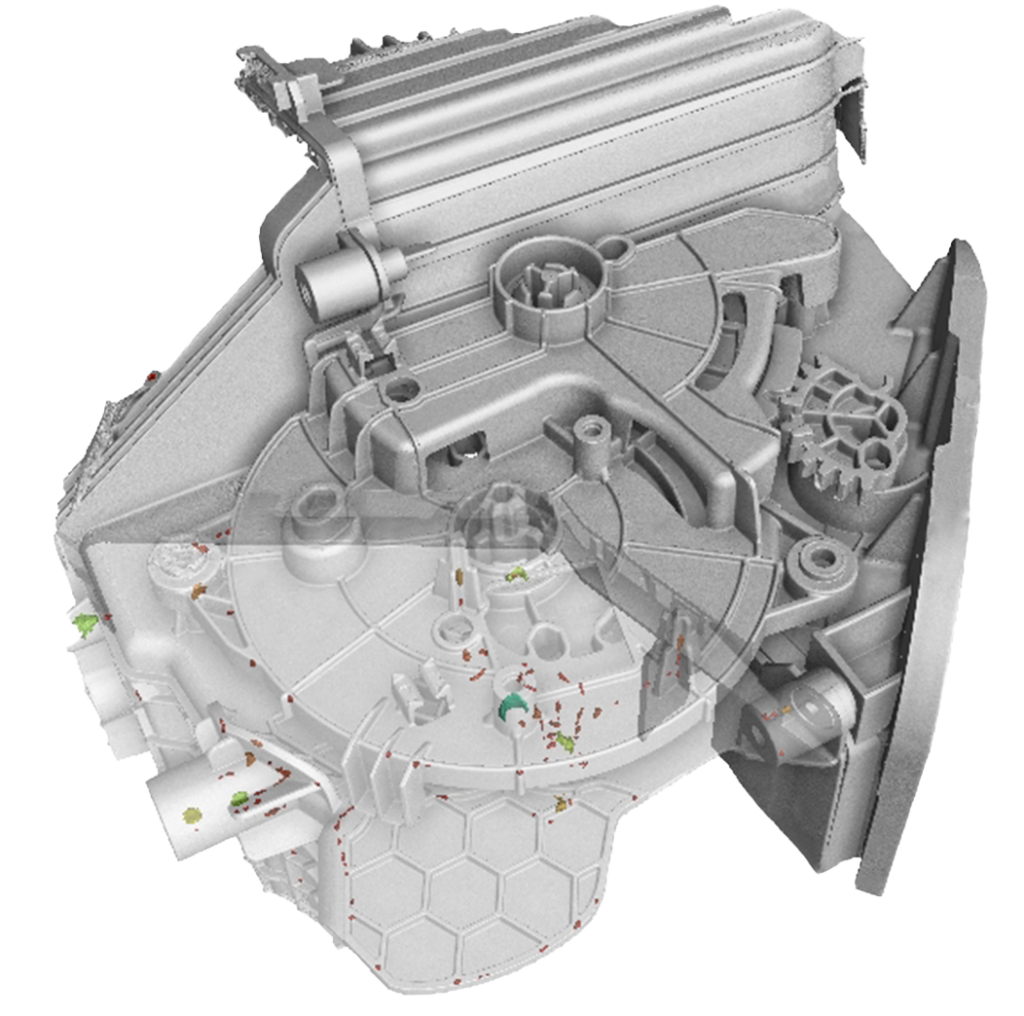

For those interested in non-destructive analysis of their parts without owning a CT system, we offer a cost-effective solution. Gain deep insights into internal structures of your sample through our micro and nano CT technology.

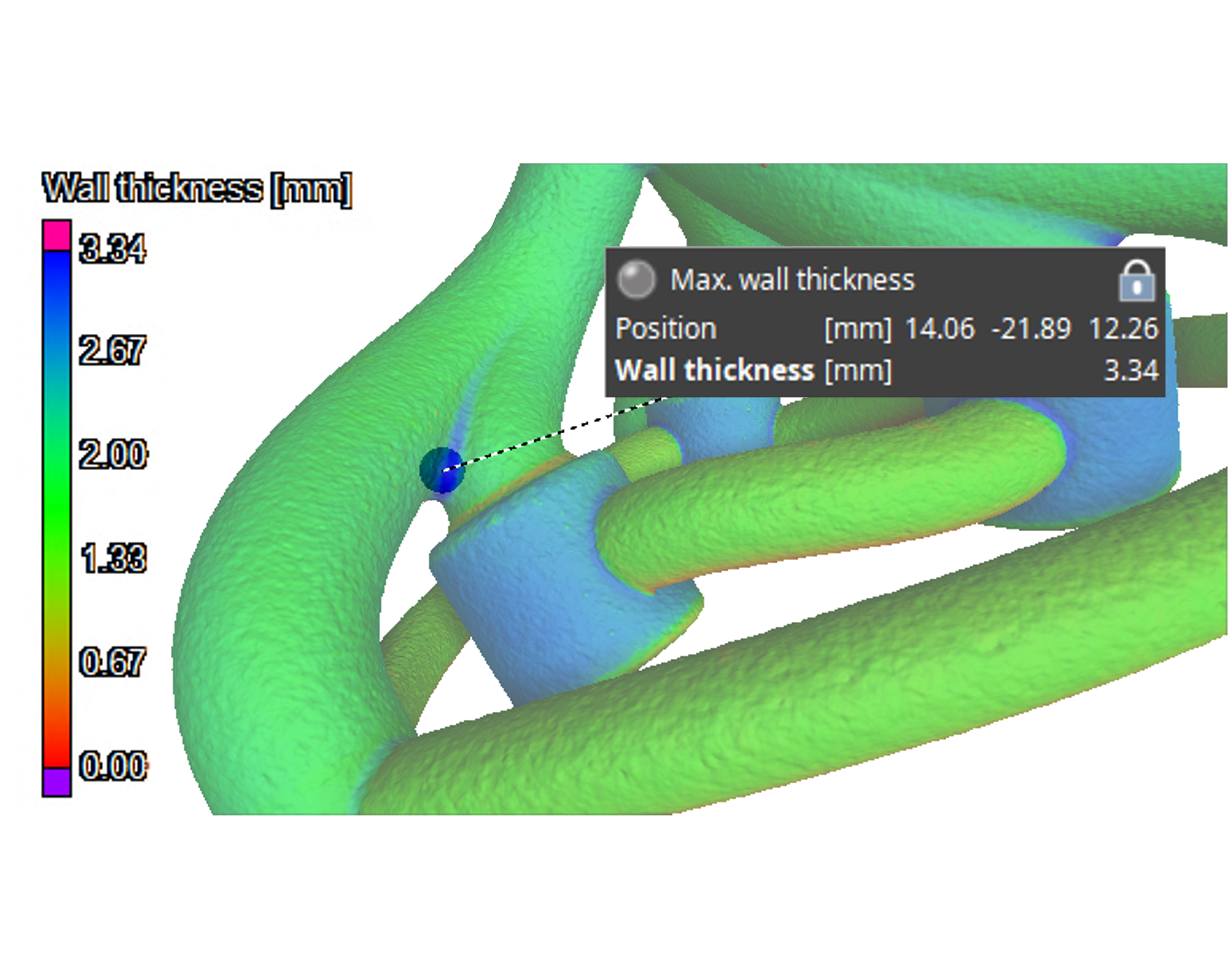

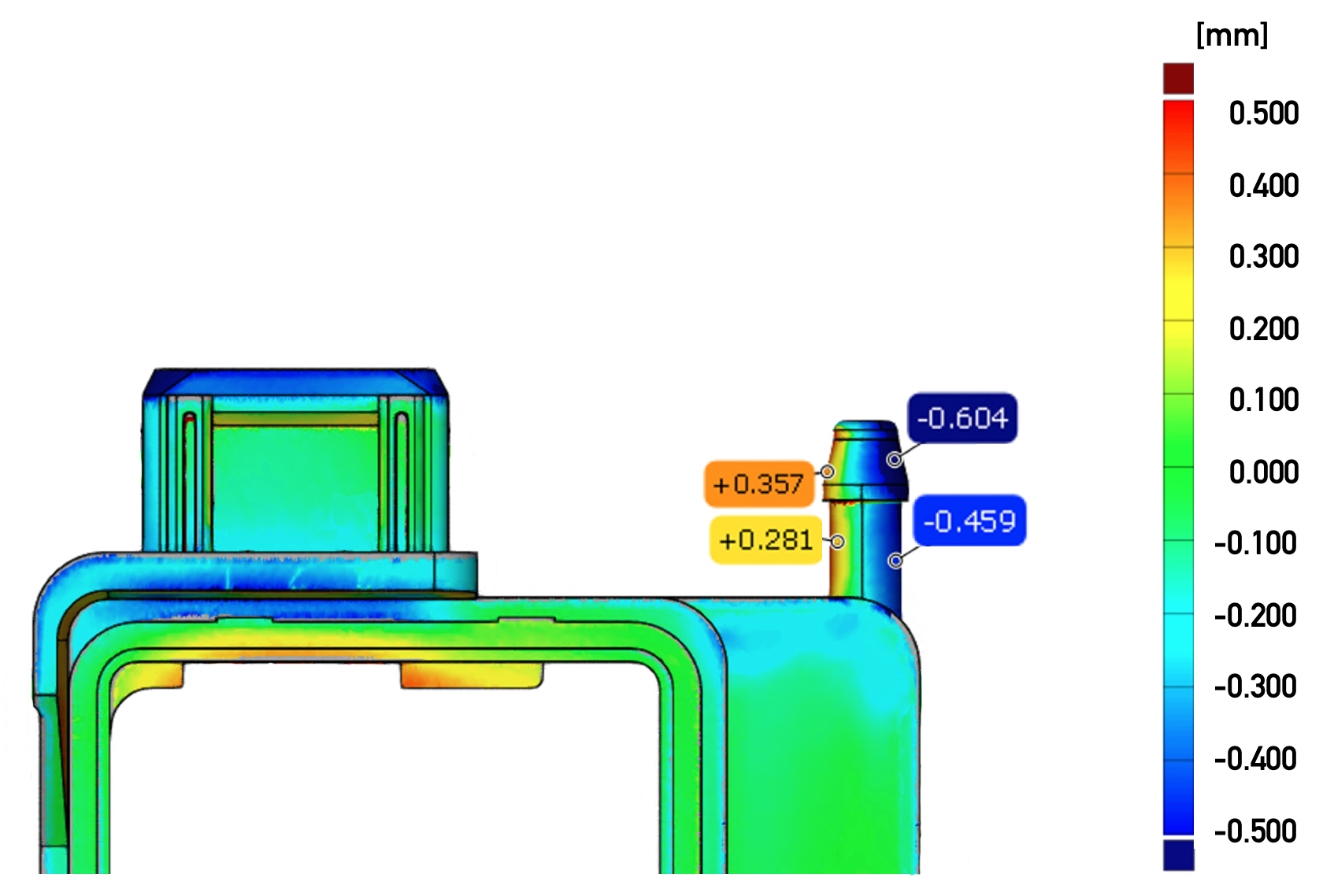

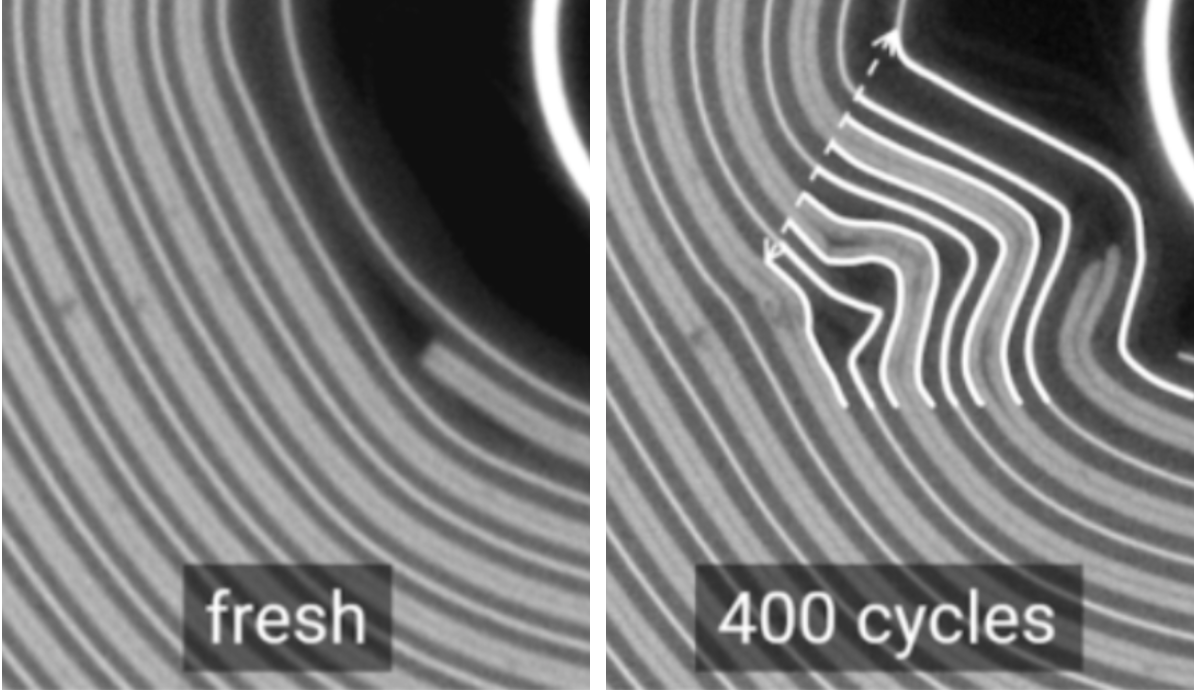

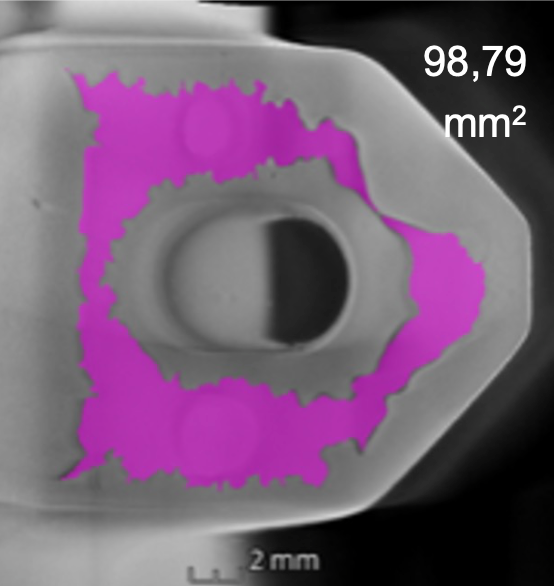

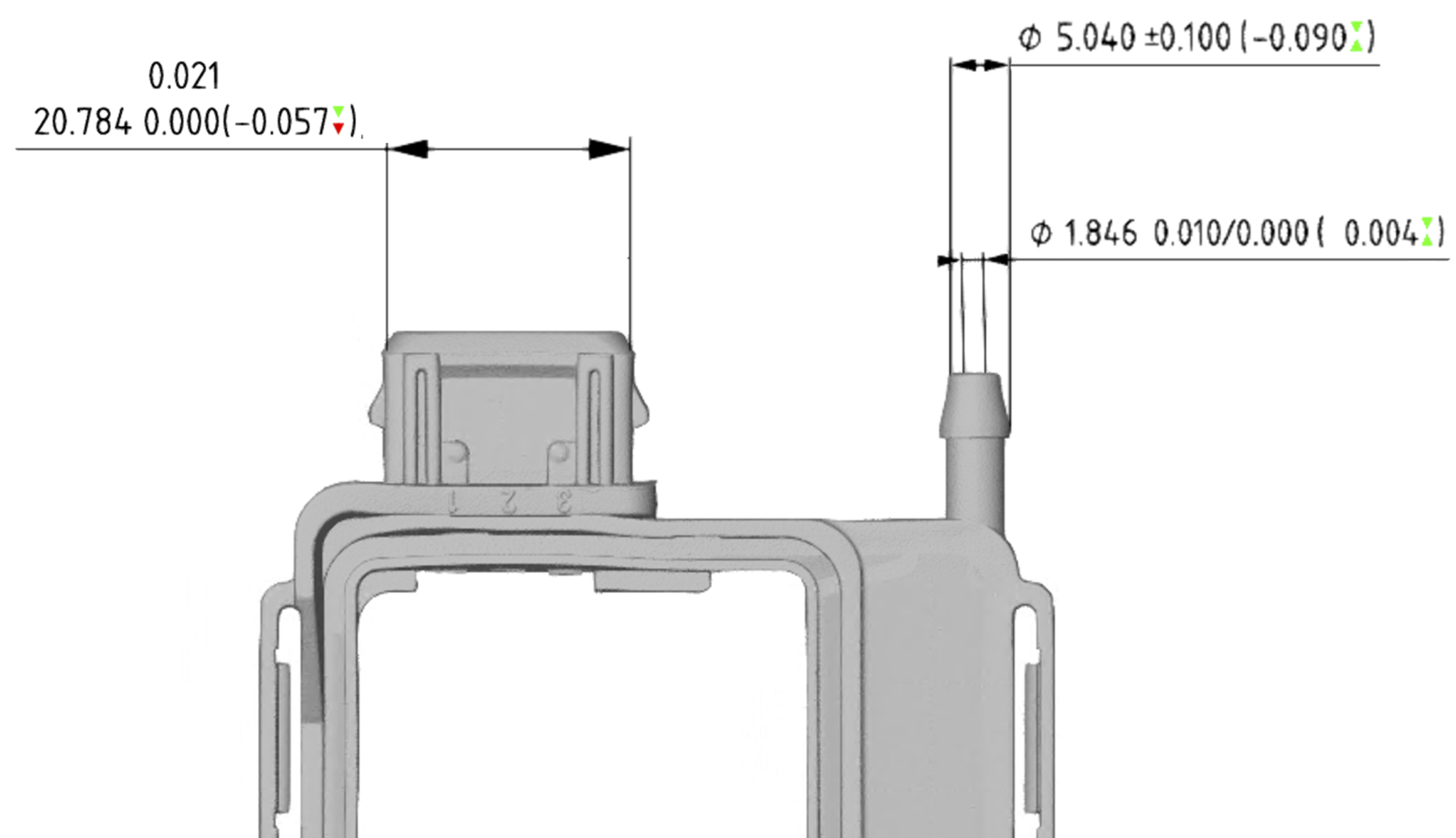

X-ray computed tomography (CT) is the best option for research and industrial quality control, catering to both R&D and quality assessment. Without damaging or altering your sample, we are able to examine intricate components and details that may not be visible through traditional methods. We’re here to make CT analysis a reality for your advancement.

Advantages of our Expertise

Quality

precise technology

ISO 9001 certified company

Know-how

experienced team

analysis according to industrial standards

Flexibility

variety of CT scanners

customer-oriented solution

Our services

Industries

X-ray CT can be beneficial across a variety of industries supporting the development, quality, and reliability of your parts.

Our Possibilities

50 kg maximum weight of the sample

dimensions up to 500 mm × 800 mm

possible resolution 0.3 µm with Field of view min 0.7 mm x 0.9 mm

4 Steps are all it takes:

Consult

Contact our experts via e-mail or phone to discuss your application and needs, and we’ll design the best solution for your requirements.

Send

Once the plan is designed, simply send us the part(s).

Scan

After delivery, we will measure your part(s) and perform analysis according to your needs.

Results

We’ll return the part(s) and provide a complete analysis, images, and tables.

Contact us

See our other products

Choose your industrial nano and micro-CT accessories from our diverse offer!

SaguaroX

Wireless micro & nano CT sample manipulation stages.

CT Phantoms

Nano & micro CT calibration, resolution estimation (ASTM E1695-95) and more.

Other accessories

CT hedgehogs, magnetic adapters, rod holders, and rigid bases.

CT principle

Industrial CT captures a series of X-ray images from different angles while the sample rotates around its axis. Subsequently using advanced reconstruction algorithms, it is possible to compute detailed cross-sectional slices. These slices together create a 3D digital volume.